Within the framework of the REVFIN project (revfin.asia), researchers are exploring new ways to characterize plastics recovered from discarded fishing gear. Current handheld spectrometers are often unsuitable for such samples: black materials cannot be measured reliably, and air gaps within nets cause light scattering that distorts results.

To address these challenges, the concept of a portable melting and analysis device has been proposed. The idea is to process small plastic samples (around 0.5 g) by melting them into uniform pellets before measurement. Since different thermoplastics—such as polyethylene (PE), polypropylene (PP), and polyamide (PA)—exhibit characteristic melting points, controlled heating between 80 °C and 250 °C could be used to identify material types with high accuracy.

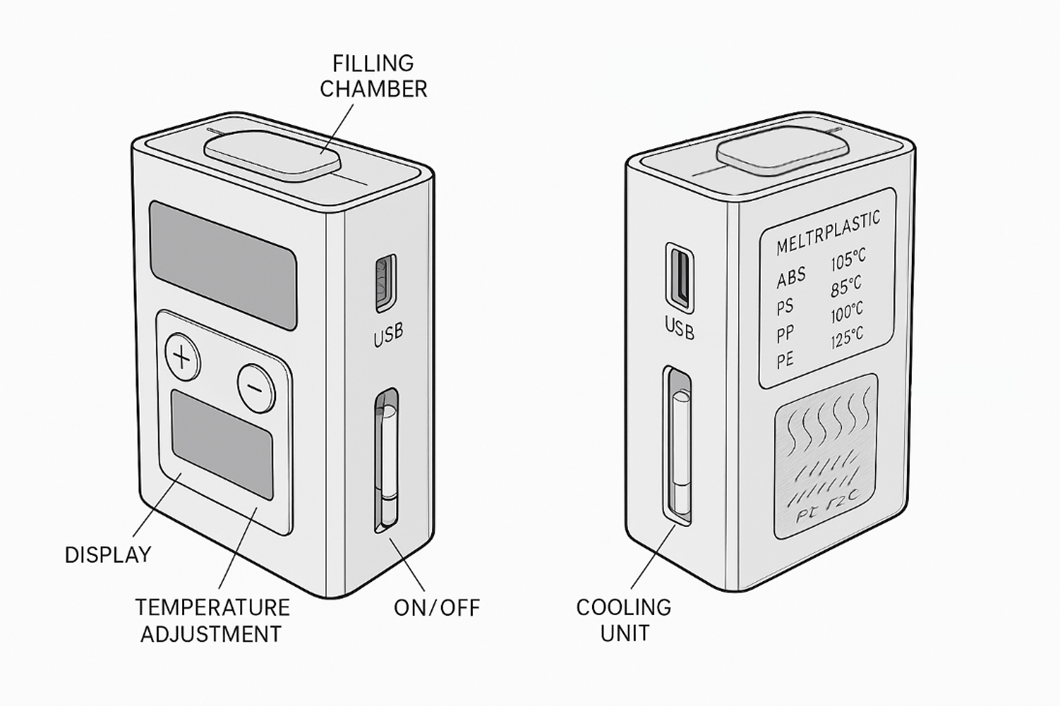

The envisioned design resembles a compact vaporizer but would be purpose-built for precise temperature control. A PID-regulated heating system, combined with thermocouples, could ensure homogeneous heat distribution. The non-stick melting chamber would be optimized for small sample volumes, producing smooth, homogeneous pellets suitable for spectroscopic or laboratory analysis.

Additional design considerations include an emission filter and cooling system for safe operation, and a rechargeable power supply for field use. Such a device could bridge the gap between laboratory-based melting point analysis and mobile field applications.

While still at the conceptual stage, this approach outlines a compact and cost-efficient method for controlled plastic melting and melting point determination. If realized, it could significantly enhance the accuracy and practicality of plastic identification in recycling, material research, and marine waste analysis.